Vf-Intelligent Vacuum Frying Machine

Zvakanakira

- Dzivirira kuparara kwemafuta anodyika neoiri, kunatsiridza kushandiswa kudzokororwa kwemafuta, Kuderedza mitengo, mafuta emukati echikafu chakakangwa akakwira kusvika 40% -50%, Iyo yemafuta yevacuum frying i5% -10%.

- Vacuum yakaderera tembiricha yekugezesa mafuta ekugezesa mvura inogona kuita kuti chikafu chakakangwa chisave nyore kudzima uye kusvibira kunogona kuchengetedza ruvara rweiyo mbishi pachayo.

- Iyo vacuum frying tekinoroji inogona kuchengetedza kunhuhwirira kweiyo mbishi pachayo.

- Kuburikidza nekudzika-kupisa frying, kuravira kwepakutanga kwechigadzirwa kunodzivirirwa.

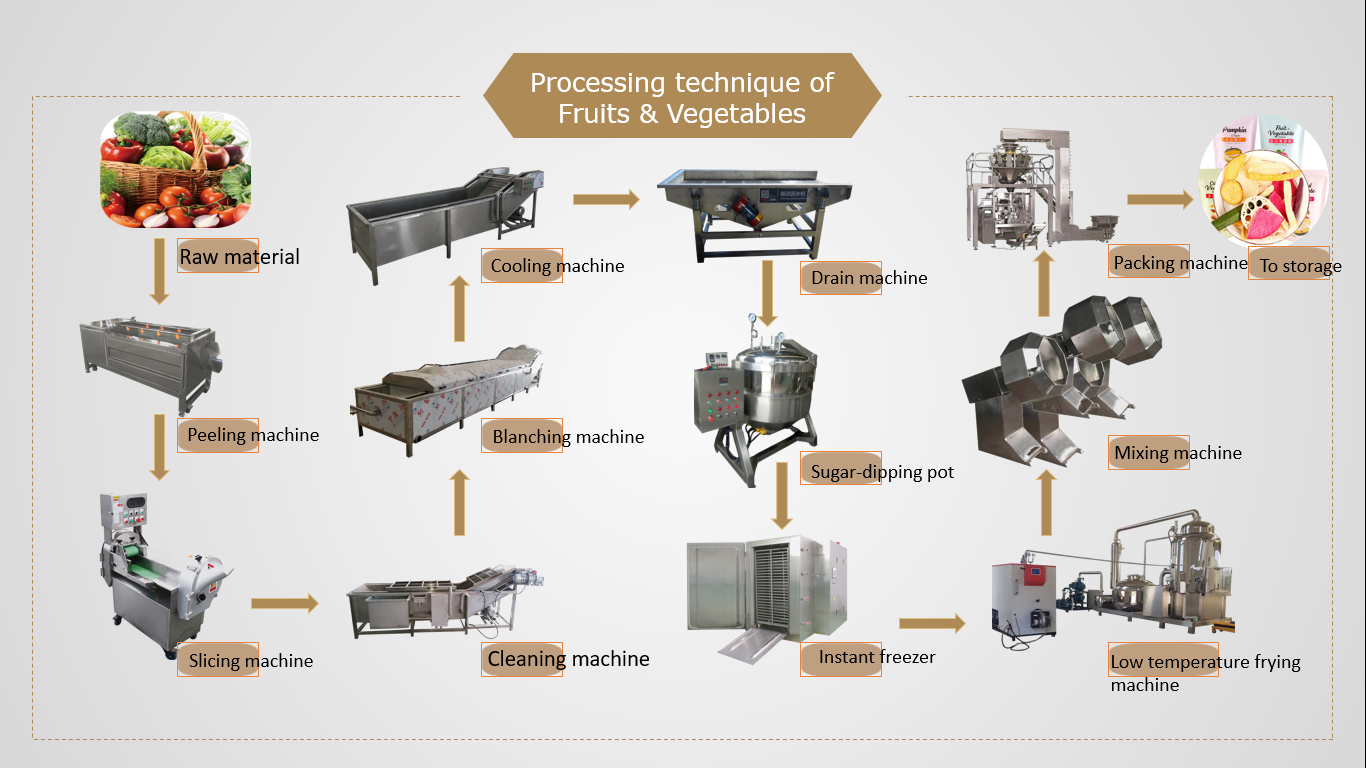

Process flow

Raw zvinhu → kuongorora → kuchenesa → kucheka (kucheka) → blanching (kudzivirira kweruvara) → kudonhedza → kuomesa nechando → kunyunguduka → kunyura (vacuum impregnation) → kuchenesa → kudhiza → vacuum frying → vacuum deoiling → seasoning → kurongedza chigadzirwa → kuchengetedza

Technical parameters

| Parameter / Model | VF-1200 | |

| Kugadzirisa simba (raw material kg/nguva) | 2400-300kg | |

| Processing nguva (min/nguva) | Inenge 50-180min | |

| Limit vacuum degree (MPA) | -0.093≈-0.098mpa | |

| Tembiricha yemafuta (℃) | 80-120 | |

| Chitubu chekudziya | Headting Source | steam |

| Kushandisa Steam (kg/h) | 300 | |

| Steam Pressure (MPA) | 0.4-1.5 | |

| Main kudziyisa nzira | Kutenderera kwekunze kwepombi yemafuta | |

| Degreasing Speed n/min | 0~400 | |

| Mvura inotonhorera (T/H) | 15 | |

| Magetsi | Elecricity Ststem | 380V |

| Total Power(kw) | 37kw | |

| Boka remidziyo rinofukidza nzvimbo ye(mm) | 5800*2200*3800mm | |

| Fryer basket uwandu (pcs) | 1 chidimbu | |

| Fryer basket sise (mm) | Diameter 1200 * 600mm | |

| Oiri tangi yekuchengetedza (L) yekudzokorodza | 2500L | |

Mhedziso yevacuum frying

Zvokudya zvinovaka muviri, kurerukirwa, kuchengetedzeka uye girinhi ndiyo nzira yekusimudzira yekugadzirwa kwechikafu.Zvibereko nemiriwo machipisi ane kuravira kwakasarudzika uye hunhu hwakachena zvakakurumbira munyika dzakabudirira uye matunhu akadai seEurope, America, Australia, Japan, Hong Kong neTaiwan.MuChina, nekuenderera mberi kwekuvandudzwa kwemararamiro evanhu, vanhu vari kuramba vachitsvaga chikafu chinonaka chinonaka.Mumaguta akabudirira akadai seBeijing, Shanghai, Yunnan, Shaanxi, Inner Mongolia, Tibet, Tianjin uye zvichingodaro, vakateverwa neushamwari nevatengi.Hapana kukurumidza kudiwa kwezvigadzirwa.

(1) Nheyo yevacuum yakaderera tembiricha yekupisa kupera mvura uye kuomesa:

Michero nemiriwo machipisi akagadzirwa nemichero mitsva nemiriwo sechinhu chikuru chemidziyo, mafuta emuriwo anodyiwa seanopisa, uye vacuum yakaderera-tembiricha yekukacha (VF vacuum) Fryer) uye humwe matekinoroji epamberi anogona kukurumidza kupera mvura uye yakaoma michero nemiriwo ine. mvura yakaderera munguva pfupi, ine mafuta akaderera, yakasvibira asi isina mafuta, ichichengetedza chimiro chepakutanga, ruvara, kunhuhwirira uye kuravira kwemichero nemiriwo, uye yakapfuma muvhitamini, mamineral, fiber uye zvimwe zvinovaka muviri, zvine zvakaderera. shuga, munyu wakaderera, mafuta mashoma, kupisa kwakadzika uye mamwe maitiro.

Para machipisi de frutas y verdurams, Frutas y Verdurams Caltamien, Y La Freidora Al Vacío de calentra de agua, en un período de tiempo muy corto, y con muy bajo contenido de aceite, los chips son crujientes pero no grasientos, se mantiene su forma, color, sabor de las frutas y verduras, además, se contiene abundante de vitaminas, , fiebres y otras nutriciones, y poco azúcar, sal, grasa, caloría y otras características.

(2) Vacuum yakaderera tembiricha yekukacha inoshanda kune chikafu siyana:

1Michero: maapuro, mabhanana, macaques, mananasi, jujube yechando, sitirobheri, jackfruit, nezvimwe.

2 Miriwo: senge karoti, radish, mbambaira, nhanga, gariki, hanyanisi, fungus inodyiwa, wax gourd, okra, nezvimwe.

3Nyama: senge nyama yemombe, fillet yehove, shrimp, octopus, nezvimwe.

(3) Vacuum frying process kuyerera:

Zvekushandisa → kuvheneka → kuchenesa → kucheka (kucheka) → cyaniding (kudzivirira kweruvara) → dhiraivha → kuomesa nechando → vacuum frying → vacuum de-oiling → seasoning → chigadzirwa kurongedza → warehousing.

Tsanangudzo yakadzama yemidziyo

Kambani yedu inounza seti yakazara yekunze vacuum yakaderera-tembiricha yekudziya tekinoroji kugadzira vacuum frying muchina kubva pakakwirira pekutangira.Iyo tekinoroji iri munzvimbo inotungamira mune imwechete indasitiri muChina.Iyo vacuum frying michina inogadzirwa nekambani yedu ndeye inopindirana mhando.

(2) Equipment kumisikidza uye kumisikidzwa runyorwa

Iyo yekuumbwa system yevacuum frying muchina ndeiyi inotevera

Vacuum frying kettle, mafuta ekutenderera kudziyisa system, vacuum system, mvura vapor capture system, otomatiki yekubvisa oiri system, magetsi ekudzora system.

(1) Iyo vacuum system ine vacuum kettle, mvura vapor trap condenser, mvura ring vacuum pombi, mvura inotonhorera system uye ane hukama mavharuvhu nemapaipi.Inoshandiswa kupukuta sisitimu uye kuchengetedza yakakwira vacuum panguva yekufinya.

(2) Iyo oiri steam yekudziya sisitimu inoumbwa yekumisa vharafu, steam solenoid valve, kuchengetedza vharafu uye ane hukama mavharuvhu, mapaipi uye ekutarisa zviridzwa.Zvekupisa mafuta ekubikisa.

(3) Iyo yemagetsi control system inoumbwa yepasirese ine mukurumbira PLC, yekubata sikirini uye yakaderera voltage yemagetsi zvishandiso, iyo inoshandiswa kudzivirira system uye otomatiki kutonga.

(4) Iyo de-oiling system inoshandiswa kuvhaira centrifugal de-oiling pakupera kwekukasira kuderedza mafuta echikafu chakakangwa.